PRODUCTS

CONTACT US

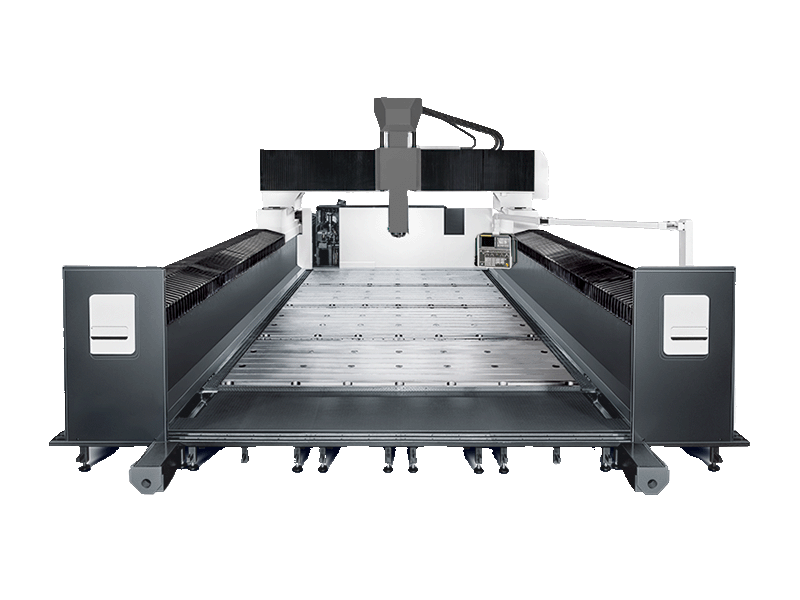

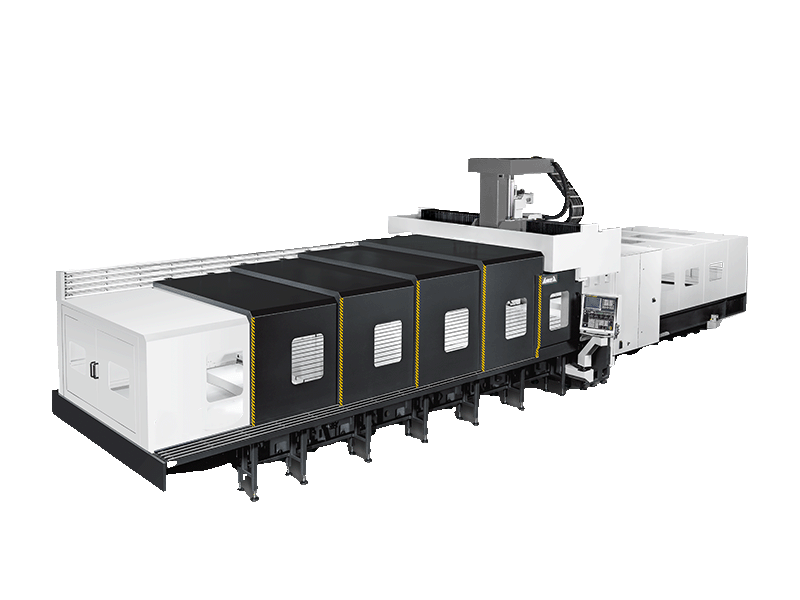

CNC Gantry Machining Center

- Commodity name: CNC Gantry Machining Center

Description

| Project |

Unit |

BL1800 |

BL2100 |

BL2500 |

BL2800 |

BL3200 |

BL3600 |

|

Trip |

|||||||

|

X-axis travel |

mm |

3000/4000/5000/6000/8000 |

|||||

|

Y-axis travel |

mm |

Standard:=ATC=Distance between two columns+200mm/AAC= Distance betveen two columns+400mm |

|||||

|

Z-axis travel |

mm |

800/1000/1250 |

800/1000/1250/1500 |

||||

|

Distance from spindle end face to worktable |

mm |

150/ Equipped Angle head350 |

|||||

|

Distance between two pillars |

mm |

1800 |

2100 |

2500 |

2500 |

3200 |

3600 |

|

Workbench |

|||||||

|

Workbench size(length) |

mm |

3000/4000/5000/6000/8000 |

|||||

|

Workbench size(wide) |

mm |

1650 |

1800 |

2200 |

2400 |

2800 |

3200 |

|

T-groove size (No*interva*wide) |

mm |

9×180×22 |

10×180×22 |

11×200×22 |

12×200×22 |

14×200×22 |

16×200×22 |

|

Maximum cutting load of the workbench |

kg |

Standard Table sze*1.2/Table size*1.5 |

|||||

|

Spindle |

|||||||

|

Spindle horse power(Consecutive /30 points)(ST) |

kw |

22/26 |

|||||

|

Range of spindle speed(ST) |

rpm |

6000/8000/10000/12000 |

|||||

|

Spindle form |

|

Gearbox/Full ooth/straight knot |

|||||

|

Spindle taper hole specification |

|

BBT 50 |

|||||

| Project | Unit | BL1800 | BL2100 | BL2500 | BL2800 | BL3200 | BL3600 |

|

Feed speed |

|||||||

|

X-axis move quickly |

mm/min |

15000 |

|||||

|

Y-axis move quickly |

mm/min |

12000 |

|||||

|

Z-axis move quicky |

mm/min |

12000 |

|||||

|

Cutting Speed |

mm/min |

10000 |

|||||

|

Positioning accuracy( Semi-closed loop) |

|||||||

|

X-axis travel |

mm |

3000/0.01 |

4000/0.015 |

5000/0.015 |

6000/0.015 |

7000/0.015 |

8000/0.015 |

|

Y-axis travel |

mm |

0.01 |

0.01 |

0.01 |

0.01 |

0.015 |

0.015 |

|

Z-axis travel |

mm |

≤ 1250/0.008 /=1500,for0.01 |

|||||

|

Repeated positioning accuracy(Semi-closed loop) |

|||||||

|

X-axis |

mm |

3000/0.008 |

4000/0.008 |

5000/0.008 |

6000/0.01 |

7000/0.01 |

8000/0.01 |

|

Y-axis |

mm |

0.005 |

0.005 |

0.006 |

0.008 |

0.008 |

0.008 |

|

Z-axis |

mm |

=15000,for0.008 |

|||||

|

Horizontal dividing head |

|||||||

|

Segmentation accuracy |

mm |

90° *4/5° *72 /1° *360 |

|||||

|

Segmentation repettion accuracy |

mm |

±3” |

|||||

|

Control system |

|

FANUC OIMF /SIEMENS |

|||||

Special configuration

|

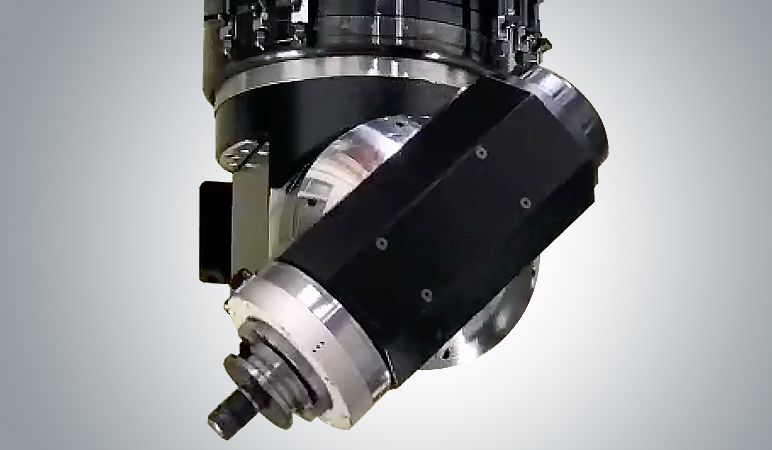

1 |

High power spindle30/37kW |

12 |

Automatic milling head exchange head library |

|

2 |

Bult-in spindle8000-20000pm |

13 |

Toggle head stand |

|

3 |

Spindle center running water(CTS) |

14 |

Fixed five-sided millng head (non-exchangeable)3+2 |

|

4 |

German planetary H/L two-stage gear box |

15 |

Fixed universal miing head (non-exchangeable)3+2 |

|

5 |

Z-axis travel ≥ 1300mm The ram increases to500×500mm |

16 |

Three axis optical ruler |

|

6 |

Hard rail square ram |

17 |

Tool measurement system |

|

7 |

Line rai square ram |

18 |

Workpiece measurement system |

|

8 |

Hard wire composite rail |

19 |

NC Rotates an axis index plate |

|

9 |

90 degree side millng head |

20 |

NC Rotates the two-axis index plate |

|

10 |

Vertical extension miling head (manual/fully automatic) |

21 |

Fully closed sheet metal (including top) |

|

11 |

AC Swing Milling head(Manual/fuly automatic) |

22 |

Voltage stabiizer |

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!