PRODUCTS

CONTACT US

Description

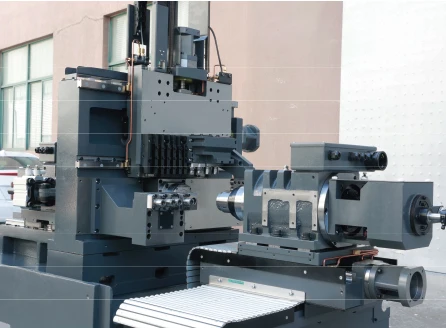

CNC System

Equipped with Taiwan's new-generation full set system and servo devices, it features dual-channel control, high efficiency, high precision and good compatibility. It can be optionally equipped with Japan's Mitsubishi system as per customer requirements.

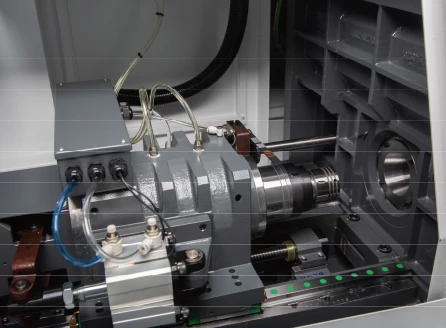

High-precision Spindle

Equipped with high-precision oil-cooled electric spindle and genuine encoder of the latest generation, the indexing accuracy is high. The cold machine controls the temperature of the electric spindle, significantly reducing the thermal deformation of the spindle. High-precision angular contact bearings are adopted to ensure high rigidity and long-term precision retention, with spindle runout ≤ 2μm.

High-performance Cast Iron

The structural design is stable. The high-quality Meehanite cast iron (microwave curing cast iron) integral bed and carriage have undergone aging treatment, featuring strong rigidity and good stability. The Z1 axis adopts roller guides, and the rigidity is even better without guide sleeves during processing

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!