Introduction to Swiss-Type Lathes: A Precision CNC Machining Solution

Release time:

Aug 08,2025

Swiss-type lathes are a specialized category of CNC (Computer Numerical Control) lathes designed to manufacture intricate, small-diameter components with exceptional precision and efficiency. Originating from the Swiss watchmaking industry, these machines have evolved significantly and are now widely utilized in various manufacturing sectors, including medical, aerospace, and electronics.

Swiss-type lathes are a specialized category of CNC (Computer Numerical Control) lathes designed to manufacture intricate, small-diameter components with exceptional precision and efficiency. Originating from the Swiss watchmaking industry, these machines have evolved significantly and are now widely utilized in various manufacturing sectors, including medical, aerospace, and electronics.

Key Features of Swiss-Type Lathes

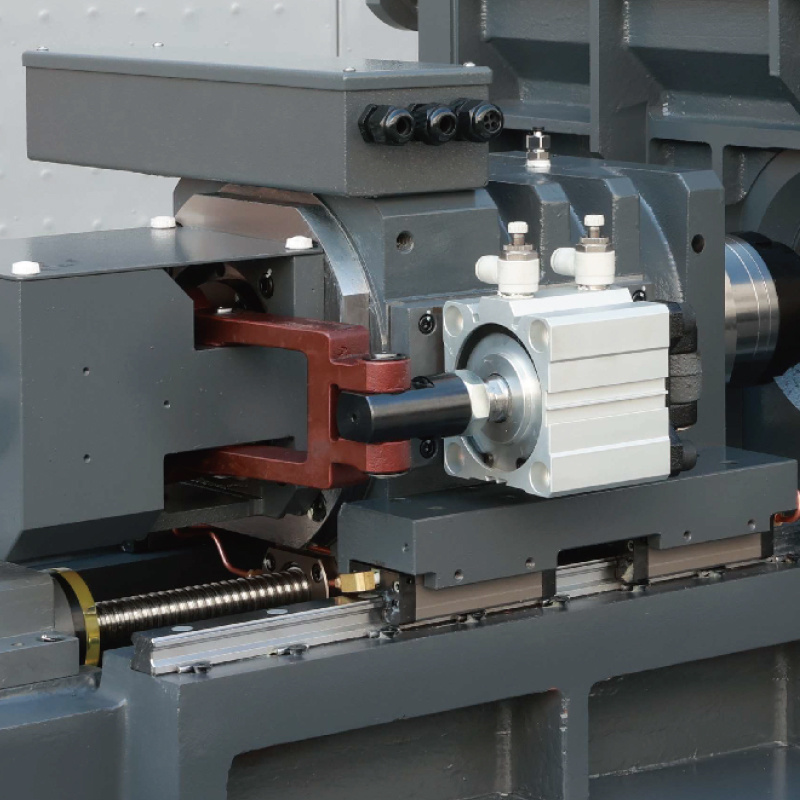

One of the defining characteristics of Swiss-type lathes is their ability to produce complex parts in a single setup. This is achieved through a unique sliding headstock design, where the workpiece is held in place and fed into the cutting tool. The cutting tools are positioned on a movable turret, allowing for multiple operations to be performed simultaneously. This design minimizes workpiece movement, significantly reducing the chance of errors associated with tool wear and dimensional drift.

Swiss-type lathes are known for their precision, capable of producing parts with tolerances as tight as ±0.001 mm. This high level of accuracy is particularly beneficial for industries where the integrity of components is critical, such as in the manufacturing of medical implants or aerospace components. The machines are typically equipped with a range of tooling options, including live tooling for milling and drilling operations, enhancing their versatility and productivity.

Comparison with Conventional CNC Lathes

While conventional CNC lathes are well-suited for larger and less complex components, Swiss-type lathes excel in manufacturing small, high-precision parts. The difference primarily lies in the way the workpiece is handled. Conventional lathes typically rotate the workpiece against a stationary cutting tool, which can limit accessibility and requires more manual setup for complex operations. In contrast, the Swiss-type lathe's mechanism allows for a more dynamic and flexible approach, enabling multiple operations to occur simultaneously without the need to reposition the workpiece.

The Swiss-type lathe is particularly advantageous in high-volume production runs, where speed and efficiency are paramount. The machine's ability to perform several machining operations at once reduces cycle times and increases throughput, making it an ideal choice for manufacturers looking to optimize their production processes.

Applications of Swiss-Type Lathes

Swiss-type lathes are employed across various industries due to their exceptional capabilities. In the medical field, they are used to produce intricate components such as surgical instruments, implants, and dental devices. The aerospace sector benefits from their precision in creating critical components like fuel nozzles and turbine blades. Additionally, the electronics sector utilizes Swiss-type lathes for manufacturing connectors, housings, and other small parts that require high levels of detail and accuracy.

As industries continue to demand higher precision and faster turnaround times, the relevance of Swiss-type lathes in modern manufacturing cannot be overstated. Their unique design and capabilities make them indispensable in producing high-quality components that meet stringent industry standards.

Swiss-type lathes represent a significant advancement in the realm of CNC machining. Their ability to produce small, complex parts with high precision, combined with their operational efficiency, positions them as a vital tool in contemporary manufacturing. As technology continues to evolve, Swiss-type lathes will likely remain at the forefront of precision machining, catering to the ever-increasing demands of various industries. Their role in enhancing productivity and ensuring quality makes them a worthy consideration for manufacturers seeking to improve their machining processes.

Related News