Cradle-Type vs. Spindle-Swinging: Key Differences in Five-Axis Machining Centers

Release time:

Jul 31,2025

The differences between cradle-type five-axis (worktable swing) and spindle swing-type five-axis machining centers, including spindle rigidity, processing efficiency, the influence of tool length on accuracy, shape error and processing range.

The five axes of a five-axis machine tool are usually composed of three linear axes and two rotary axes, but their structural forms vary greatly. Different structural forms can cause some differences in the machine tool's rigidity, dynamic performance, and precision stability.

This article mainly analyzes and compares two different structures of five-axis machine tools: the vertical spindle swing and the vertical spindle stationary with the worktable swing (cradle type), so as to enable users to fully understand their structural forms and thus facilitate their selection of suitable machine tools based on the characteristics of their products and economic capabilities.

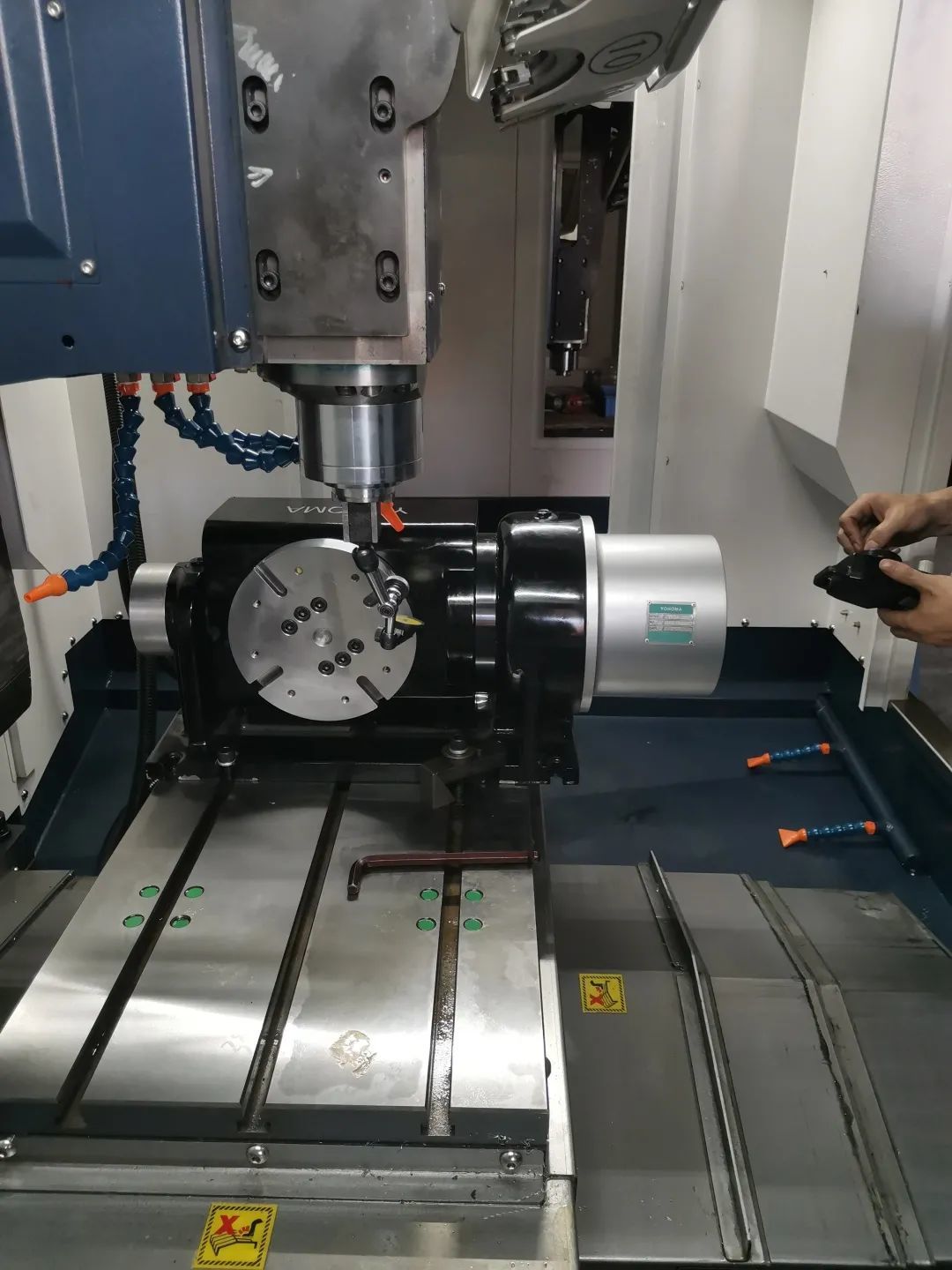

Cradle type main shaft swinging type

1. Comparison of the rigidity of the machine tool spindle

During the processing of the head-swing machine tool, the spindle swings, which makes the rigidity of the spindle relatively poor; while for the worktable-swing machine tool, since it is the worktable that swings, it does not have any impact on the rigidity of the spindle.

2. Comparison of the processing efficiency of the machine tools

Due to the different rotation points, when the tool tip achieves the same displacement, the spindle of the head-swing machine tool needs to swing at a larger angle (similar to the lever principle), so when processing the same part, the efficiency of the head-swing machine tool is lower.

3. Influence of tool length on the machining accuracy of the machine tool

Swing error = swing arm x swing angle. For the head-swing machine tool, the tool length is part of the swing arm. That is to say, in the case of head-swing, the tool length affects the length of the swing arm and amplifies the error. That is, the error will increase as the tool length increases. For the cradle-type worktable-swing machine tool, the tool length has no relation to the length of the swing arm.

4. Position Error and Shape Error

Both types of machines will generate position errors during oscillation. However, the head-swing machine will also produce shape errors, while the worktable-swing machine will not. In the head-swing machine, the tool rotates, causing position errors. At the same time, the feed direction of the machined hole and the rotation center of the tool deviate, so while position errors occur, shape errors also arise, resulting in wedge-shaped holes.

In contrast, the position error of the worktable-swing machine is caused by the worktable's oscillation. The feed direction of the spindle and the rotation center of the tool always coincide, so no additional shape errors are generated. This is another obvious advantage of the cradle-type worktable swing over the head swing.

5. Comparison of the Size Range of Five-Axis Machining

As the spindle of a head-tilting machine tool swings, the machining range in the diameter direction of the workpiece will be reduced. That is to say, when the spindle swings, it will consume the travel, resulting in the maximum diameter range of workpieces that can be machined by five-axis machining being smaller than that of three-axis machining. However, the worktable-tilting machine tool's worktable swing does not affect the horizontal dimension of the workpiece. In this sense, the size range of workpieces that can be machined by five-axis and three-axis machining is the same. However, the maximum range of workpieces that can be machined by five-axis machining also needs to consider the interference caused by the machine structure. Users should ask the machine tool supplier to provide a five-axis machining interference diagram for analysis and comparison. Generally, for the same travel, the five-axis machining range of a machine tool with a cradle-type worktable swing structure is larger than that of a head-tilting machine tool.

Therefore, the cradle-type worktable swing machine tool has better spindle rigidity and higher machining efficiency; the length of the tool does not affect the machining accuracy, and there will be no shape error in the machining; for the same travel, the five-axis machining range of the machine tool is larger than that of the head-tilting machine tool.

The spindle rigidity of the head-tilting machine tool is relatively poor, and the machining efficiency is relatively low; the machining accuracy will decrease with the increase of the tool length; there will be shape errors in the machining; when the spindle swings, it will consume the travel, resulting in a smaller maximum workpiece size that can be machined.

In addition, it should be noted that the worktable-tilting machine tool needs to overcome the self-weight of the workpiece. If the workpiece is very heavy, it has higher requirements for the fixture. Moreover, when machining large and heavy parts, the machine tool cannot achieve worktable swing and can only use the head-tilting method.

Related News