The usage characteristics of five commonly used chip removal machines for CNC lathes

Release time:

Jun 27,2025

The chip remover for CNC lathes, also known as the CNC lathes chip conveyor, is used to transport the metal chips cut off by the metal cutting machine to a designated position.

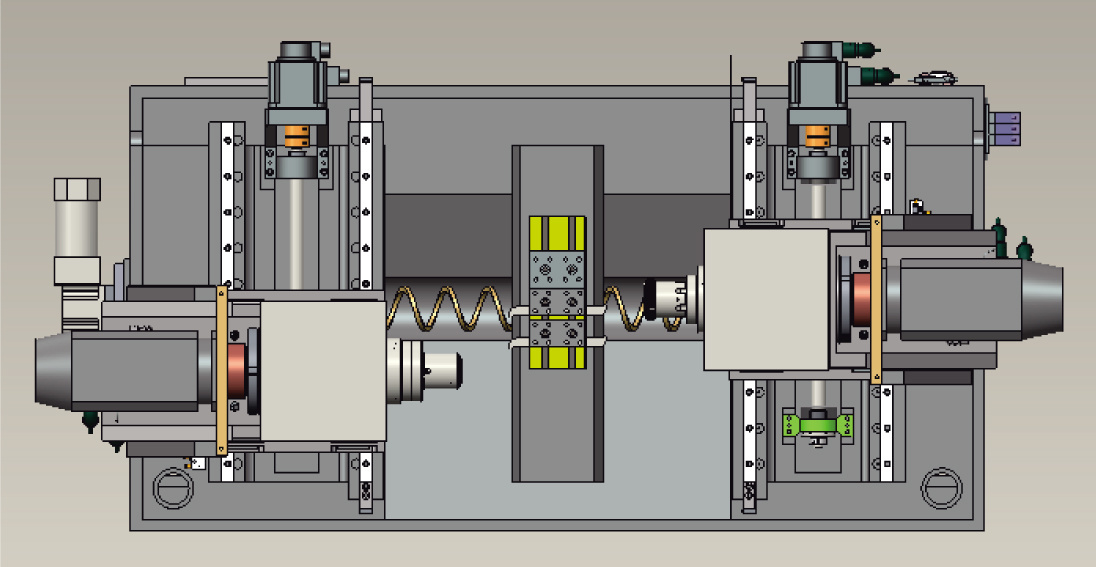

The chip remover for CNC lathes, also known as the CNC lathes chip conveyor, is used to transport the metal chips cut off by the metal cutting machine to a designated position. The classification of machine tool chip removers/chip conveyors: It is divided into chain plate type chip removal conveyor, scraper type chip removal conveyor, magnetic type chip removal conveyor, and spiral type chip removal conveyor. The main features of various types of CNC lathes chip removers:

Ⅰ. The scraper-type chip removal conveyor system, with its scraper chip removal equipment, has a wide selection range for conveying speed, high operational efficiency, and diverse effective chip removal widths. It can provide sufficient application scope, such as CNC machines, machining centers, grinding machines, and automated lines. It performs well in dealing with metal chips and abrasive particles during grinding processes, as well as in removing aluminum shavings in the automotive industry. The scraper is equipped with specially designed chains at both ends.

Ⅱ. The height and spreading distance of the scrap removal plate can be randomly designed. Therefore, the transmission is smooth, the structure is compact, and the strength is good. Moreover, according to the user's requirements, steel mesh backflushing, scrap removal devices, vortex separators, oil-water separators, etc. can be added to form an integrated filtration system, improving the surface processing accuracy of the product, saving coolant, reducing the labor intensity of workers, and it is a widely used auxiliary equipment for machine tools.

Ⅲ. Spiral Chip Discharge Conveyor This equipment is driven by a reducer, which rotates a shaft with spiral blades to push the materials forward (backward). The materials will gather at the discharge port and fall into the designated area. This machine has a compact structure, occupies a small space, is easy to operate, has few transmission links, and has an extremely low failure rate. It is particularly suitable for use in machine tools where the chip-discharging space is limited and other chip-discharging methods are not feasible.

Ⅳ. Chip Collector The chip collector is used to collect various types of chips conveyed from the machine tool by the chip separators. It is equipped with wheels at the bottom, allowing the chips to be sent out of the work area for convenient collection and sorting. There are two types: dry and wet. The dry chip box can tilt and the chips can be discharged directly. The wet type is based on the dry type and is equipped with a double-layer filter screen and an oil valve to separate the cooling waves from the chips, achieving recovery and environmental protection effects. And according to different chip discharge volumes and user requirements, various chip collector vehicles with different volumes and functions can be designed.

When processing on a CNC lathe, the first step is to prepare the program based on the part drawing. The programming codes and instruction patterns mostly conform to ISO standards and corresponding national standards. Then, the program is input into the NC or CNC system through an information carrier. The CNC system issues instructions according to the program content. On one hand, the motor in the control system controls the lathe to perform the movement of the part. On the other hand, it controls other auxiliary movements of the lathe, such as the spindle speed, direction selection, start/stop of the cooling pump, etc. The two actions work together to complete the processing content.

Related News