The advantages and disadvantages of slant-bed and flat-bed machine tools

Release time:

Jun 19,2025

The WUXI RUIEN CNC lathe is equipped with advanced control systems that allow for seamless operation and programming, optimizing productivity and reducing setup time.

Comparison of machine tool layout

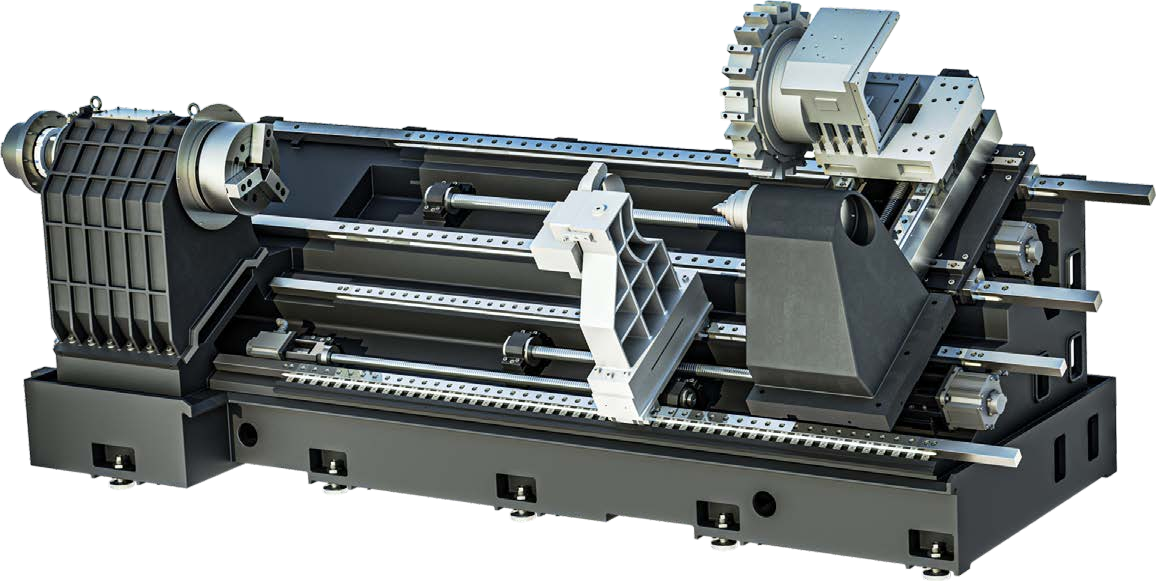

The two guide rails of the flat-bed CNC lathe are located in a plane parallel to the ground plane. The two guide rails of the slant-bed CNC lathe intersect with the ground plane, forming an inclined plane. The angles are 30°, 45°, 60°, and 75°. Viewed from the side of the machine tool, the bed of a flat-bed CNC lathe is square, while that of a slant-bed CNC lathe is right-angled triangular. Obviously, under the same guide rail width, the X-direction drag plate of the inclined bed is longer than that of the flat bed. The practical significance of this application in lathes is that more tool positions can be arranged.

Slant-Bed CNC lathe

Comparison of cutting rigidity

The cross-sectional area of a slant-bed CNC lathe is larger than that of a flat-bed lathe of the same specification, that is, it has stronger resistance to bending and torsion. The tool of a slant-bed CNC lathe cuts from the upper part of the workpiece at an Angle to the lower part. The cutting force is basically in the same direction as the weight of the workpiece, so the spindle operates relatively smoothly and is less likely to cause cutting vibration. However, when a flat-bed CNC lathe is cutting, the cutting force generated by the tool and the workpiece forms a 90° Angle with the weight of the workpiece, which is more likely to cause vibration.

Comparison of processing accuracy

The transmission lead screw of a CNC lathe is a high-precision ball screw. The transmission clearance between the lead screw and the nut is very small, but it does not mean there is no clearance. As long as there is a clearance, when the lead screw moves in one direction and then drives in the opposite direction, a reverse clearance is inevitable. The presence of a reverse clearance will affect the repeat positioning accuracy of the CNC lathe, thereby affecting the processing accuracy.

The layout of the slant-bed CNC lathe can directly affect the clearance of the ball screw in the X-direction. Gravity acts directly on the axial direction of the screw, making the reverse clearance during transmission almost zero. The X-direction lead screw of a flat-bed CNC lathe is not affected by axial gravity, and the clearance cannot be directly eliminated. This is the inherent precision advantage that the design brings to the slant-bed CNC lathe.

lathe bed

Comparison of chip removal capacity

Due to the effect of gravity, slant-bed CNC lathes are less likely to cause tool entanglement, which is conducive to chip removal. At the same time, when combined with the central lead screw and guide rail protection sheet metal, it can prevent chips from accumulating on the lead screw and guide rail. Slant-bed CNC lathes are generally equipped with automatic chip conveyors, which can automatically remove chips and increase the effective working time of workers. The structure of the flat bed makes it difficult to install an automatic chip conveyor.

Comparison of automated production

The increase in the number of tool positions on machine tools and the configuration of automatic chip conveyors are actually laying the foundation for automated production. One person on duty for multiple machine tools has always been the direction of machine tool development. When a slant-bed CNC lathe is further equipped with a milling power head, an automatic feeding machine or a mechanical hand, it can automatically load materials, complete all chip cutting processes in one clamping, automatically unload materials and automatically remove chips, thus becoming an automatic CNC lathe with extremely high working efficiency.

The WUXI RUIEN CNC lathe is equipped with advanced control systems that allow for seamless operation and programming, optimizing productivity and reducing setup time. Its user-friendly interface and high-speed spindle capabilities make it ideal for a wide range of applications, from intricate parts to large-scale production.

Built with high-quality components, the WUXI RUIEN lathe promises durability and reliability, ensuring minimal downtime and maximizing your investment. Whether you are in the automotive, aerospace, or general manufacturing sectors, this CNC lathe will elevate your machining processes to new heights.

Related News