What is turning and milling compound?

Release time:

Jun 11,2025

With the increasing variety of CNC lathes, the names of many lathes have gradually become difficult to understand.

With the increasing variety of CNC lathes, the names of many lathes have gradually become difficult to understand. Next, let's take a look at what CNC turning and milling compound is. Before understanding CNC turning and milling compound, we need to separately understand CNC lathes and CNC milling machines to see what the differences are between them.

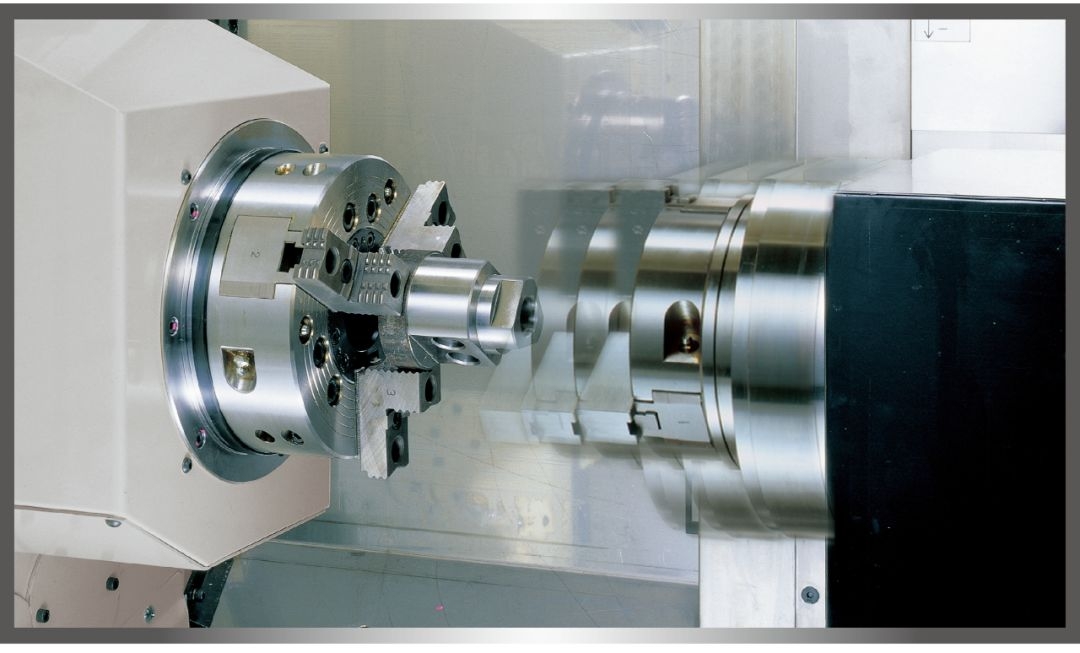

A CNC lathe refers to a machine tool that primarily uses the cutting tools of a CNC lathe to perform turning operations on rotating workpieces. Generally, it refers to the fact that the cutting tool

of a lathe is fixed at a specific position on the machine tool. The workpiece rotates along the axis under the clamping of the fixture and is cut when approaching the cutting edge. Therefore,

it is mainly suitable for processing shafts, discs, sleeves and other workpieces with reversing surfaces, and is the most widely used type of machine tool in mechanical manufacturing and repair

factories. Common rotary processing machines such as CNC milling machines and drilling machines all originated from CNC lathes. Its processing principle is that the workpiece is rotating while

the cutting tool remains stationary

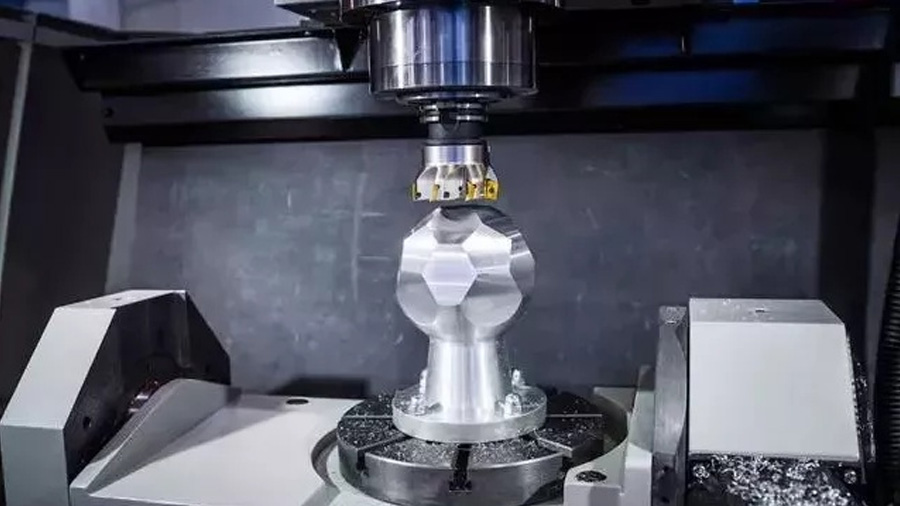

A CNC milling machine refers to a machine tool that mainly uses milling cutters to process various surfaces on workpieces. Its manifestation is that the rotational motion of the milling cutter is

the main motion, and the movement of the workpiece and the milling cutter is the feed motion. That is to say, its object is fixed at a certain position on the machine tool. The milling cutter rotates

at high speed under the clamping of the fixture. When touching the workpiece, it processes planes and grooves on its surface. It can also process various curved surfaces, gears, etc. A CNC

milling machine is a machine that uses a milling cutter to mill workpieces. On a CNC milling machine, it can process planes (horizontal planes, vertical planes), grooves (keyways, T-slots, dovetail

grooves, etc.), splined parts (gears, splined shafts, sprockets, helical surfaces (threads, helical grooves), and various curved surfaces. In addition, it can also be used for processing the surface

and inner holes of the rotating body and performing blocking operations, etc. Due to the multi-tool intermittent cutting, the productivity of CNC milling machines is relatively high. The processing

principle of CNC milling machines is that the workpiece remains stationary while the tool rotates.

As the name suggests, a CNC turning and milling compound is a compound machine tool that integrates all the functional features of a CNC lathe and a CNC milling machine. Its functions include

turning and milling compound, turning, milling and grinding compound, and milling and grinding compound. The purpose of the compound is to enable a machine tool to have multiple functions.

It can complete multiple tasks with one clamping. It enhances processing efficiency and accuracy as it integrates the features of a CNC lathe into a single machine, significantly reducing floor space

and lowering capital costs such as rent. Although the unit price of CNC turning and milling compound is relatively high, due to its ability to shorten the manufacturing process chain and the number

of tooling fixtures, reduce workshop floor space and lower equipment maintenance costs, from the perspective of enterprise investment, it can also effectively reduce the overall investment in fixed

assets and significantly lower the costs of production operation and personnel and equipment management

Related News