Follow-up Grinding Machine and Related Knowledge

Release time:

Sep 05,2025

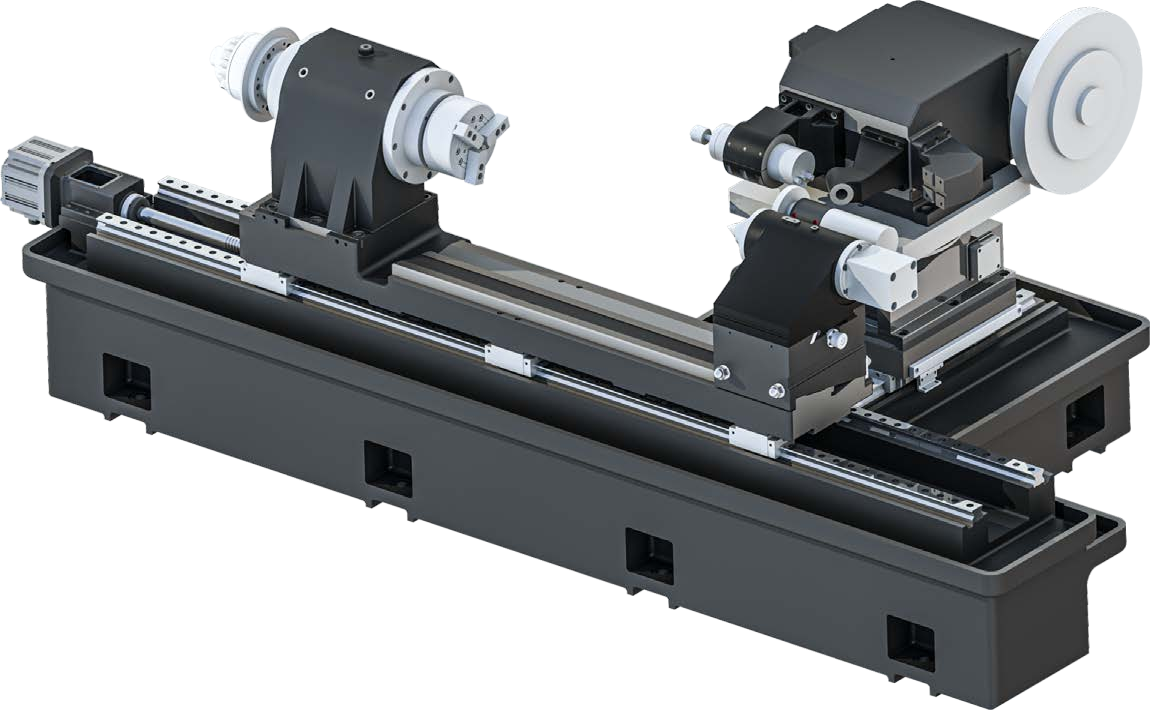

The servo grinding machine is a highly efficient and precise grinding machine, suitable for grinding various shafts, discs and other parts. To improve processing quality and equipment lifespan, operators need to strictly follow the operation procedures and conduct regular maintenance and upkeep. At the same time, they need to constantly learn and master new processes and technologies.

Follow-up grinding machine is a kind of efficient and high-precision grinding machine, suitable for grinding processing of various shafts, discs and other parts. This article will introduce the follow-up grinding machine from aspects such as its structure, working principle, operation method and maintenance.

I. Structure of Servo Grinding Machine

The follow-up grinding machine mainly consists of the bed, worktable, grinding head, grinding wheel, cooling system, hydraulic system, etc.

The bed is made of high-quality cast iron and has internal reinforcing ribs, which enhance the rigidity and stability of the bed.

The grinding head can move up and down to adapt to workpieces of different heights.

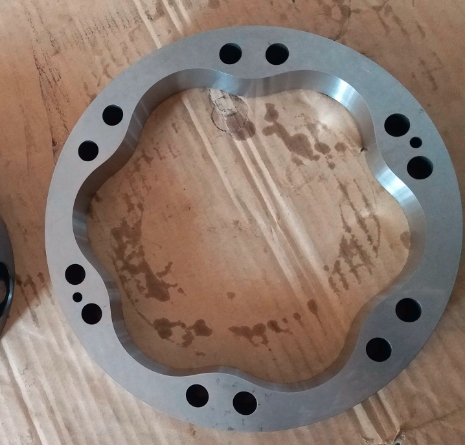

It can grind non-circular, arc, gear-like, cam and other shapes. The inner and outer arc surfaces of rotors and stators are typical processing scenarios.

The follow-up movement is accomplished through the coordinated operation of the X, Y, and C axes, and it can also be linked with the Z axis to achieve depth grinding.

The grinding head is supported by high-precision rolling bearings, enabling high-speed rotation and feed.

The grinding wheel is made of super-hard materials such as diamond or cubic boron nitride, and it features high hardness and high wear resistance.

The cooling system, composed of a coolant tank and a pump, is used to cool the grinding head and workpiece, thereby enhancing the processing accuracy.

The hydraulic system, composed of a hydraulic station and oil cylinders, is used to drive the up and down movement of the worktable.

II. Working Principle of Follow-Grinding Machine

The working principle of the follow-up grinding machine mainly involves grinding the workpiece with the grinding head. Specifically, the grinding wheel is installed on the main shaft of the grinding head, and the surface of the grinding wheel is made of super-hard materials such as diamond or cubic boron nitride, which can achieve high-speed rotation. The workpiece is fixed on the worktable, and the contact with the grinding wheel is achieved through the up and down movement of the worktable. During the grinding process, coolant is continuously sprayed on the grinding head and the workpiece to remove the grinding heat and prevent the workpiece from overheating and deforming. At the same time, the hydraulic system drives the up and down movement of the worktable to maintain a certain grinding pressure between the workpiece and the grinding wheel.

III. Operating Methods of Follow-up Grinding Machine

Preparatory work

Before operating the servo grinding machine, the following preparations are required:

(1) Check whether all components of the grinding machine are in good condition and whether there is any looseness.

(2) Check whether the power, hydraulic, cooling and other systems are functioning properly;

(3) Prepare the workpiece and tools, and determine the processing plan;

(4) Adjust the height of the workbench so that the workpiece and the axis of the grinding wheel are basically aligned.

Operation steps

(1) Fix the workpiece on the workbench and adjust the height of the workbench to the appropriate position.

(2) According to the processing plan, adjust the feed rate and speed of the grinding head;

(3) Start the grinding machine and carry out the grinding process;

(4) According to the processing requirements, constantly adjust the position of the grinding head and the feed rate;

(5) After the processing is completed, turn off the grinding machine, remove the workpiece, and clean the site.

Notes for Attention

When operating a servo grinding machine, the following points should be noted:

(1) Keep all the components of the grinding machine clean to prevent debris and dust from entering.

(2) During the operation, the speed and feed rate of the grinding head must not be adjusted at will.

(3) During the processing, one should constantly monitor the progress and promptly address any issues that arise.

(4) After the operation is completed, the site should be promptly cleaned up to maintain its cleanliness.

IV. Maintenance and Care of Servo Grinding Machines

In order to extend the service life of the servo grinding machine and improve the processing accuracy, regular maintenance is necessary. The specific contents include:

Regularly check whether the connecting bolts of each component of the grinding machine are loose. If any are loose, tighten them immediately.

Regularly inspect the operation of hydraulic, cooling and other systems, and keep them clean and unobstructed.

Regularly clean the grinding wheel and the filters in the cooling system to prevent blockages and wear.

Regularly check whether the electrical components are aging or damaged. If any are damaged, replace them immediately.

Carry out comprehensive cleaning and maintenance of the equipment on a regular basis to keep it clean and in good condition.

Related News