Top 5 Reasons to Choose a Double Column Machining Center from WUXI RUIEN

Release time:

Jul 09,2025

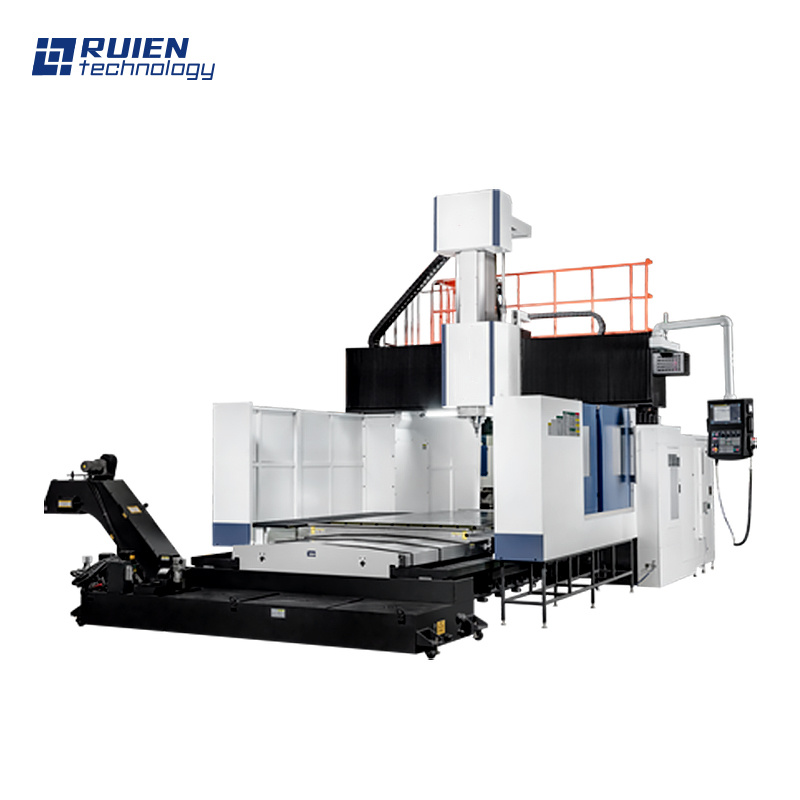

WUXI RUIEN is proud to present our state-of-the-art Double Column Machining Center, designed to elevate your manufacturing capabilities.

When it comes to precision manufacturing and complex machining applications, choosing the right machining center is critical to achieving optimal results. Among the various options available, the Double Column Machining Center stands out for several compelling reasons.

Ⅰ. Enhanced Stability and Rigidity

One of the foremost advantages of a Double Column Machining Center is its structural design, which provides enhanced stability and rigidity. The double column configuration minimizes vibration during machining operations, allowing for high-precision cuts and finishes. This is particularly crucial for industries that require tight tolerances, such as aerospace and automotive manufacturing. Compared to Bridge-type Machining Centers, which may exhibit more flexibility under certain loads, the double column design offers superior performance in demanding machining scenarios.

Ⅱ. Large Work Envelope

Double Column Machining Centers typically feature a larger work envelope compared to many other CNC machine tools. This expanded capacity allows for the machining of larger workpieces without the need for multiple setups, thereby increasing efficiency. When working with sizeable components, such as molds or large structural parts, the ability to accommodate greater dimensions is a significant advantage. The spacious work area also enables the integration of complex fixturing systems, further enhancing flexibility and capability.

Ⅲ. Multi-Axis Machining Capabilities

In the realm of advanced machining, multi-axis capabilities are crucial for producing intricate shapes and contours. Many Double Column Machining Centers are equipped with 5-axis machining capabilities, enabling simultaneous movement along multiple axes. This feature allows for the machining of complex geometries in a single setup, reducing cycle times and improving overall productivity. In contrast, traditional Bridge-type and other CNC machine tools may require additional setups or tool changes, which can slow down production and increase the potential for errors.

Ⅳ. Versatility Across Industries

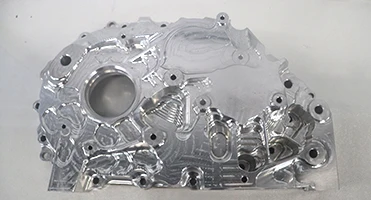

The versatility of Double Column Machining Centers makes them suitable for a wide range of applications across various industries. From aerospace to mold-making, these machines can handle diverse materials such as metals, composites, and plastics. Their ability to switch between different machining operations—such as milling, drilling, and tapping—on a single platform streamlines workflows and reduces the need for additional equipment. This adaptability is a significant advantage in today’s fast-paced manufacturing environments, where the ability to respond to changing demands is critical.

Ⅴ. Long-Term Investment

Investing in a Double Column Machining Center can yield long-term benefits for manufacturers. Although the initial capital expenditure may be higher than that of some other CNC machine tools, the enhanced productivity, reduced cycle times, and improved quality can lead to significant cost savings over time. Additionally, the durability and reliability of double column machines often result in lower maintenance costs and fewer downtimes, further contributing to their overall value.

WUXI RUIEN is proud to present our state-of-the-art Double Column Machining Center, designed to elevate your manufacturing capabilities. Engineered for precision and efficiency, our machining center is perfect for handling large workpieces with utmost accuracy. The robust double column structure provides enhanced stability, allowing for superior machining performance even under demanding conditions.

Related News