The processing range of the gantry machining center

Release time:

Mar 25,2025

The processing range of the gantry machining center | WUXI RUIEN TECHNOLOGY CO.,LTD

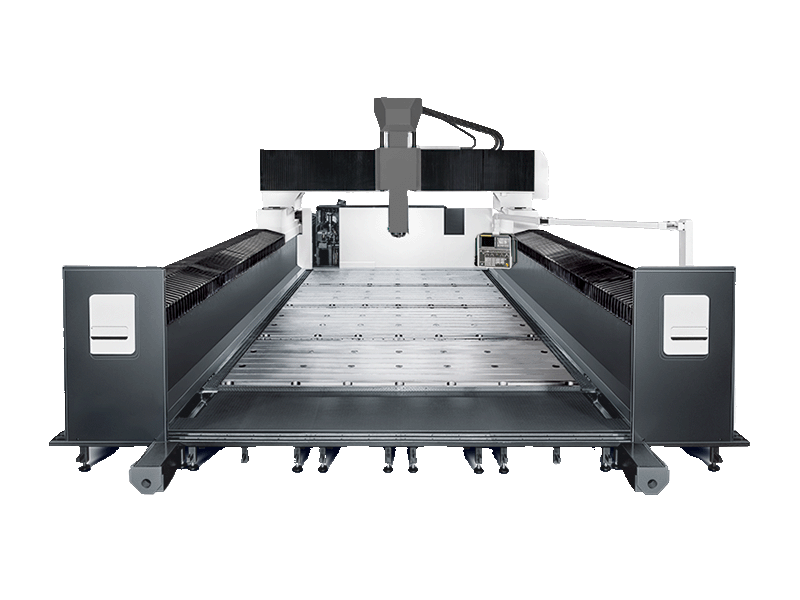

The gantry machining center is a sophisticated piece of machinery that plays a pivotal role in modern manufacturing and machining processes. This type of machining center is specifically designed to handle large workpieces, making it an essential tool in industries such as aerospace, automotive, and heavy machinery. The key characteristic of a gantry machining center is its gantry design, which consists of a fixed beam that spans over the worktable, allowing for an efficient and versatile machining process.

One prominent variant of this technology is the Gantry Fixed Beam Processing Center. This particular configuration is known for its rigid construction and stability, which are crucial when machining intricate parts with tight tolerances. The fixed beam in this system provides enhanced support and reduces vibrations during operation, resulting in improved precision and surface finish on machined components. Operators can achieve complex shapes and intricate designs due to the extensive range of motion available in both the X and Y axes, along with the ability to adjust the Z-axis for vertical machining.

The processing range of a gantry machining center varies significantly depending on the model and manufacturer, but typically, it allows for substantial movement across the axes. For instance, a standard gantry machining center might offer an X-axis stroke of 3,000 mm, a Y-axis stroke of 1,500 mm, and a Z-axis stroke of 600 mm. This extensive processing range enables the machining of large components, such as engine blocks, molds, and frames, which are commonly used in various industries.

CNC lathe integration with gantry machining centers further enhances their capabilities. By combining the functionalities of both machines, manufacturers can optimize their production processes. While the CNC lathe is primarily designed for turning operations, such as shaping cylindrical parts, the gantry machining center allows for milling, drilling, and various other machining processes. This synergy enables a single setup to complete multiple operations, minimizing the need for part transfers and reducing overall production time.

Moreover, the programming capabilities of modern gantry machining centers, often facilitated by advanced CNC (Computer Numerical Control) systems, allow for intricate machining paths and automated operations. Operators can input complex designs directly into the computer system, which translates the digital model into precise machining instructions. This capability not only streamlines the production process but also ensures repeatability and accuracy across multiple production runs.

In conclusion, the gantry machining center, particularly the Gantry Fixed Beam Processing Center, represents a significant advancement in the field of machining technology. Its ability to accommodate large workpieces, coupled with the integration of CNC lathes, offers manufacturers a powerful solution for achieving high precision and efficiency. The processing range of these centers allows for the production of complex parts across a variety of industries, reinforcing their importance in the modern manufacturing landscape. As technology continues to evolve, the capabilities and applications of gantry machining centers will undoubtedly expand, further solidifying their role as a cornerstone of advanced machining processes.

Related News