Understand the characteristics and process of machining center

Release time:

Feb 08,2025

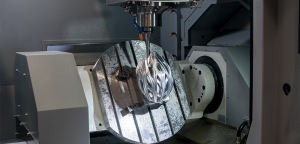

Machining center processing refers to the automatic processing of materials based on the program, can carry out such processing machinery called machining center.

This introduction to the use of machining center machining center processing characteristics, processing procedures, etc.

What is machining center machining?

Machining center machining is a type of cutting process using processing machines called machining centers. The position of the tool is automatically controlled based on the input program and the shape of the 3D drawing. It also automatically changes the tool, so it does not need to use different equipment or change the tool for each process, and can process complex shapes faster. It has the advantages of being able to process with less equipment and machining shapes that are difficult to process with previous equipment.

Machining center The characteristics of the machining center used for machining

In the machining center, by making the cutting tool rotate at a high speed, the material is cut and the target shape is formed. It can also be considered as a kind of milling processing. It is characterized by the ability to automatically process by setting NC program and the ability to automatically change multiple tools.

According to the preset program, it can automatically replace the tool that matches the required material and condition, cut the surface, open the slot and open the hole. With machining center processing, milling processing equipment has a general milling machine, NC milling machine.

Comparing these with machining center processing, general milling machine can not carry out automatic processing with automatic replacement function and program, NC milling machine can carry out automatic processing, but can not automatically replace the tool.

Type of equipment | Program machining | Automatic tool change |

Machining center | 〇 | 〇 |

NC milling machine | 〇 | × |

Universal milling machine | × | × |

Type of machining center

Machining centers The machining centers used in machining are divided into the following four categories.

Vertical machining center\Horizontal machining center\Door type machining center\5-axis machining center

Vertical machining center

Vertical machining centers are installed in a vertical (upright) direction with respect to the ground surface of the equipment to process materials from above. The rotary axis equipped with the tool moves in the direction of vertical, horizontal and height, so it can confirm the machining appearance of the machining center from above while processing.

Smaller than horizontal, can also be installed in a narrow setting space. It is a widely introduced type, but the chips generated during processing are difficult to discharge to the outside, so it is easy to produce faults caused by chips.

Compared with mass production, it is more suitable for small production of multiple varieties.

Horizontal machining center

The type of material to be processed from the lateral installation of the rotating shaft with the tool. The chips generated during processing will fall down. Compared with vertical machining centers, it is not easy to produce faults caused by cutting.

In addition, the equipment is different, and sometimes a device can be added to automatically carry parts. Therefore, it is possible to process materials continuously, which is suitable for cases where the same part is desired to be produced in large quantities.

Gantry machining center

The Gantry machining center is the same as the vertical machining center, which is also the vertical machining center of the tool. However, the rotary axis of the tool in the vertical machining center is cantilever type, while the gantry machining center is supported from both sides by the double columns configured for the transverse workpiece. The ability to process large parts over several meters is a big feature, and the machining center itself is very large.

5-axis processing machine (5-axis machining center)

5-axis processing machine (5-axis machining center) is the latest machine in cutting technology. It is a machining center with two rotating axes in addition to the vertical, horizontal and height axes. In the vertical and horizontal machining center, the staff manually rotate the material, even if the processing needs to be located here, as long as the 5-axis machining center, without the staff hands, can automatically make the rotation positioning. And there is no need to stop the equipment in order to replace the process, can be continuous processing.

Most of them are vertical, but there are also processing centers that can rotate the head for 5-axis processing in the gantry processing center, which plays a role in the manufacturing workshop of aircraft parts.

Quality is also improved due to increased processing efficiency and reduced error in the replacement process. On the other hand, there are also some shortcomings, such as the high price of the machinery itself, high processing costs, thick cutting difficulties, rarely able to use a machining center to complete the whole process. In addition, the difficulty of creating processing procedures, including rotation, is also a major obstacle to the introduction of processing machines.

Related News