Introduction to the Basics of Centerless Grinding Machines | WUXI RUIEN

Release time:

May 21,2025

The WUXI Ruien Centerless Grinder is a state-of-the-art machine designed for high-precision grinding applications. This advanced equipment excels in producing cylindrical components without the need for a central axis, making it an ideal choice for various manufacturing processes. The centerless grinding technology ensures superior dimensional accuracy and surface finish, significantly enhancing overall productivity.

What is centerless grinding?

Centerless is a precise grinding method that can remove chips, burrs, marks and cuts to a specific size without any fixed positioning (such as spindle installation).

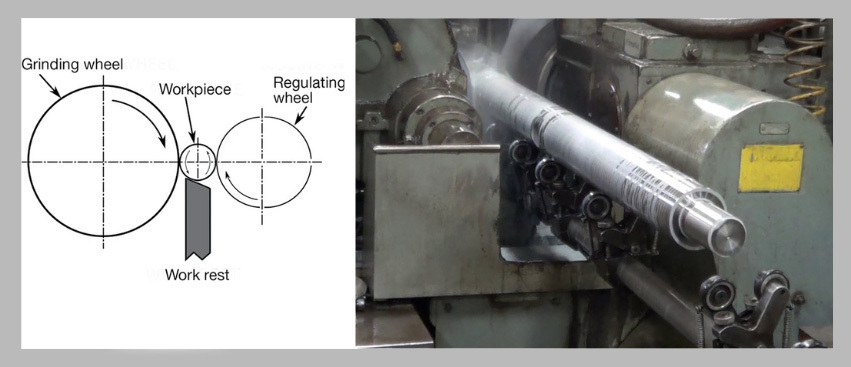

The main difference lies in the operation procedure, as the centerless process does not involve using a center or chuck to fix the workpiece. To understand its mechanism, you need to know its three elements: the grinding wheel, the adjusting wheel and the supporting tool.

Grinding wheel: A main cutting tool with an abrasive layer on its surface, similar to traditional grinding.

Regulating wheel: Another round mechanism (axially parallel) controls the control speed and axial feed rate of the main wheel of the workpiece.

Rest blade: It is placed between the two wheels. It supports the workpiece and maintains its position during the grinding process.

Centreless grinding process

Here, the combination and control of these three parts determine the accuracy of the final surface finish result. The latest centerless grinding Settings can also automate the grinding path and other parameters, such as feed rate, grinding wheel speed, positioning, etc.

Centerless grinding process: How does it work?

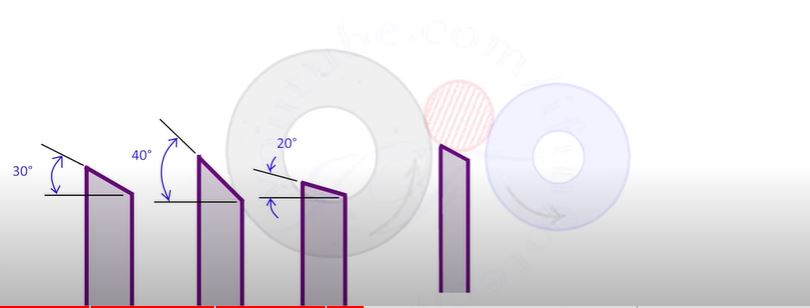

As mentioned earlier, the centerless device for metal grinding involves a combination of a rotating wheel, an adjusting wheel and a working bracket. But how do they seamlessly collaborate to perform grinding operations? The top Angle of the remaining part of the blade is conducive to the rounding action of the workpiece. If the tip Angle of the blade increases, rapid rounding will occur. In addition, the higher Angle also weakens the rigidity of the blades.

The position of the workpiece rest blade in centerless grinding

The common top angles of the workpiece rest blade are 20°, 30°, and 40°. However, vibration increases with the increase of Angle. Therefore, for heavy workpieces, a small Angle is preferred.

In addition, the regulating wheel is usually made of rubber or plastic, and the type of grinding material depends on the material you are grinding.

The following are general abrasives for different substrates;

Carbon | Steel Alumina |

Stainless Steel | Silicon Carbide |

Aluminum Plate | Silicon Carbide |

Hardened Steel | Cubic Boron Nitride |

High-speed Steel | ceramic alumina |

Acrylic | Diamond |

Nylon | Alumina |

Centerless Grinding

The following are the typical steps of the centerless grinding process.

Blade and wheel setting: First, adjust the Angle between the regulating wheel and the working blade.

Align the wheels: Check if the two wheels are completely aligned. Slight deviations may cause irregularities on the surface.

Speed setting: Set the speed of the grinding wheel and adjustment wheel according to the material type and the required surface finish (Ra value).

Feeding the workpiece: The workpiece is placed on the workpiece rack blade and fed in through wheels. The adjusting wheel pushes the workpiece towards the grinding wheel, and the grinding wheel removes the material until the surface does not reach the expected smoothness.

Continuous monitoring and adjustment: Monitor the speed, pressure or Angle of components throughout the process and make adjustments when necessary.

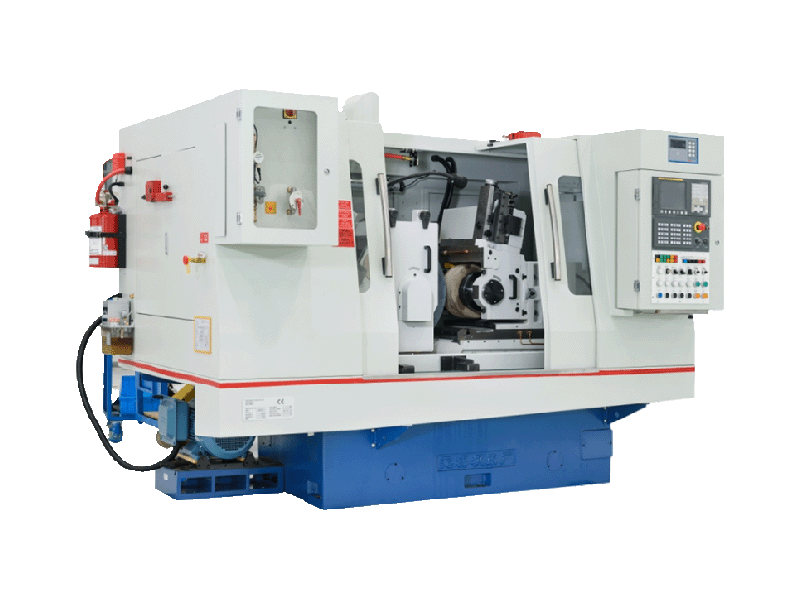

The WUXI Ruien Centerless Grinder is a state-of-the-art machine designed for high-precision grinding applications. This advanced equipment excels in producing cylindrical components without the need for a central axis, making it an ideal choice for various manufacturing processes. The centerless grinding technology ensures superior dimensional accuracy and surface finish, significantly enhancing overall productivity.

WUXI Ruien's centerless grinders are equipped with robust features, including adjustable grinding wheels, superior coolant systems, and user-friendly controls that facilitate easy operation and maintenance. These machines are suitable for a wide range of materials, from metals to plastics, catering to diverse industries such as automotive, aerospace, and medical.

Investing in WUXI Ruien's centerless grinding technology not only optimizes your manufacturing efficiency but also reduces operational costs. Our commitment to quality and innovation ensures that you receive reliable equipment tailored to your specific needs. Experience the precision and performance of WUXI Ruien Centerless Grinders and elevate your production capabilities to new heights.

Related News